We are flexible, welcome to contact us if any question.

PLA is a biopolymer made from plant-derived sugars that are fermented and converted into lactic acid. The lactic acid molecules then link to form rings called lactide monomers, which then link together to create a chain of polylactide polymer.

No. PLA and other bio-based plastics are made from plant materials, often corn. Not all bio-based plastics are degradable. Some petroleum-based plastics can biodegrade. Degradable additives are claimed to work in many resins. A degraded material is an opportunity lost to reuse a valuable resource.

No. There are two distinct sets of materials involved in the degradable question.

One set of degradable plastics are materials such as PLA (Polylactic Acid) that are unique plastics for which biological degradation potential is part of the nature of the plastic.

The second set is materials of the standard #1 PET, #2 HDPE, #4 LDPE, #5 PP and #6 PS with special degradable additives included. The mechanisms for degradation vary with additive type.

Because less energy is used to produce the PLA pellets. Up to 65% less fossil fuel and 65% less greenhouse-gas emissions than when making traditional plastic.

100 bushels of corn are equal to 1 metric ton.

No. HYF will not degrade on shelves and has a similar shelf-life to other petroleum based plastics.

HYF plastic offers more end-of-life options than any other material. It can be physically recycled, composted industrially, incinerated, put in landfill and even recycled back into it′s original lactic acid state.

Yes. To request a sample, visit our "Contact Us" section and submit your request by email.

What is different about HYF, is that it has an excellent heat seal range, making it an easy transition from most OPP films on typical packaging equipment.

With a range of 150 to 210°F (65-98°C), most heat seal machines require the temperatures of the sealing bar to be turned down considerably to produce a good seal, and another common change is to reduce the dwell time as well to maximize seal strength.

A common mistake is to try to run it too hot. If there is distortion around the seal and/or the film becomes brittle and cracks or breaks at the seal, the sealing bar temperature is probably too hot. Turn the temp down to make a better seal, and save some energy in the process!

Due to its unique process, HYF films are exceptionally heat resistant. With little or no dimensional change with processing temperatures of 60°C (and less than 5% dimensional change even at 100°C for 5 minutes).

No need. It has been corona treated.

The printing inks is same as the printing inks you are using, UV or solvent based is ok.

--- Please store it in low temperature( 20℃);

--- Do not expose to rapid temperature changes

--- Do not store in direct sunlight

--- For mechanical, moisture and dust protection, store film in its original packaging.

Suggest that it is used within 12 months from the production date.

HYF packages two ways, vertical (which is the usual manner of shipment.) and horizontal for some of our larger sizes. We have two sizes of paper cores, six inch (153mm) and three inch (76mm).

For vertical packaging, the roll is wrapped with film with corepads attached to the ends of the roll by inserting plastic plugs into the core. The roll is then wrapped with thermal insulation film for protection.

For horizontal packaging the roll is wrapped with polyethylene film and set on fumigation-free plywood end boards. The rolls are then strapped to each other and to the pallet. Finally, each pallet is then stretched wrapped prior to shipment.

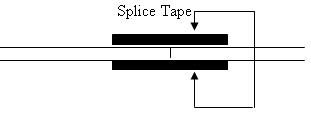

The number of splices is listed on the production label.

If a customer has a special product need, HYF would take appropriate action after confirming and discussing the issue with the customer.

Heat shrinkable film is unlike other film substrates. You must take care that the film is stored at or below the temperature suggested to prevent premature shrinkage from occurring. Care must also be taken in storing the film after printing, and in shipping film to co-packers or end-users. Some natural shrink information is provided for you on each specification sheet. This goes for all shrinkable film.

No. None of HYF's PVC, PETG shrink films are Corona treated. HYF film can be successfully printed without Corona treating. If you wish to Corona treat the film, please treat immediately prior to printing.

For PVC and PLA shrink film, the glue is Cyclohexanone

For PETG shrink film, the glue is 1.3 dioxane.

Our PVC shrink film is blown.

It should be shipped by reefer container in +15℃ with air.

Yes, you can.

For PVC and PETG shrink film, one small roll sample with 200m could be provided as free sample, but the transportation fee is afforded by your side.

For PLA shrink film, the sampling fee and transportation need be afforded by your side.

Small order could be accepted. However, due to the features of shrink films, reefer container is suggested to be used during the shipment.

--- Please store it in temperatures above 30℃ (86°F) or below 10℃ (50°F)

--- Do not expose to rapid temperature changes

--- Do not store in direct sunlight

--- For mechanical, moisture and dust protection, store film in its original packaging.

Polyvinyl chloride (PVC) and Polyethylene Terephthalate Glycol-modified (PETG) are two commonly used shrink sleeve materials.

PVC – Easiest to control, generally the most cost-effective and offers good scuff resistance. Unit cost is less and it works better on some applications than PETG. There are two types of PVC – high shrink PVC and standard PVC.

PETG – Offers the best scuff resistance, has the highest percentage of shrink ability and easily recyclable. It’s also more stable and readily available. More customers are choosing PETG over PVC because it’s more readily available.

You can request a quote by speaking with us online or send emails. For a firm quote, it is better to provide us the type of film with detailed size and quantity.

Copyright © HUBEI HYF PACKAGING CO., LTD. All Rights Reserved | Sitemap

| Powered by

SEOKeywords:Shrink Wrap Film Customized Biodegradable Shrink Film Pvc Shrink Film Rolls Flexible Packaging Film Petg Shrink Film Properties Custom Printed Shrink Film High Shrink Petg Shrink Film China Pvc Shrink Wrap Film Shrink Sleeve Plastic Label Films Shrink Sleeve Packaging Pvc Shrink Film Manufacturing Process Pvc Super Clear Shrink Film Heat Shrink Film Roll Pvc Shrink Film For Bottle Label Price Shrink Wrap Uses China Shrink Film Pvc Clear Shrink Film