And compared to several traditional packaging alternatives, flexible film packaging is more environmentally friendly and better value for money. As a result, flexible films are used in almost every industry. PLA flexible films supplier is here to introduce you to the benefits of flexible films in the packaging industry.

Flexible packaging film is touted because it can be customized to fit the details of the product being packaged. Regardless of shape, size or visual requirements, the solution gives you the flexibility to customize your packaging to your unique specifications and market objectives.

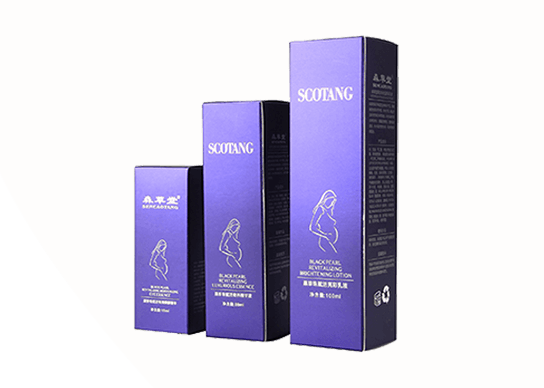

Customization elements also extend from materials to visual attributes, including clarity, gloss and printability. It allows you to truly showcase your products and brand in an eye-catching way. You can print high-quality graphics in a variety of colors and designs, package your products with creativity and style, or include important information directly on the package.

Flexible packaging films are designed with many product needs and practicalities in mind. Flexible films help extend the shelf life of perishable items and can hide the odor of the package contents.

LDPE films are used to package rice and grocery products. The former is often used to encapsulate electronic components.

Stand-up zipper bags are often used to package pet food, candy, milk powder, etc.

Laminated aluminum foil bags are used for tablet packaging, face masks, IC board packaging and other applications.

Laminated pouches with one-way valve. Common uses include various powders, pet food, etc.

Vacuum packaging bags and pouches can be used for seafood, frozen prepared foods, etc.

Steaming pouches are used to package seasonings, sauces, meat products and other edible preparations.

Standard laminated pouches and sachets are used to package products in the food, pharmaceutical and cosmetic sectors.

Because flexible films can be customized to the specific size of your product, there is no need to use more material than is absolutely necessary. By using high-quality film, you can often gradually eliminate the need for additional packaging components such as corrugated pallets and the corresponding costs. In addition, the cost of implementing flexible packaging film, from materials to production costs, is significantly lower than that of plastic or glass containers. Because of their light weight, flexible packaging films are more affordable for domestic and international shipments. As new technologies continue to emerge, you can further reduce packaging costs by downsizing or choosing smaller widths of film.

Polylactide, polylactic acid (PLA), is extruded into film, also known as polylactic acid film or PLA film. PLA flexible film is made from corn, wheat, cassava and other starch-containing organisms as starting materials, enzymatically digested to obtain glucose, then fermented by acid bacteria to lactic acid, and finally compounded to obtain a biodegradable thermoplastic polyester. PLA has good biocompatibility, environmental safety, non-toxic, good mechanical properties, light transmission and processing properties. It can be used in various packaging materials such as floor film, food packaging bags and pharmaceuticals.

HYF sells PLA flexible films and we serve customers all over Europe with high quality films and latest product innovations in shrink sleeve packaging, pharmaceutical industry and biodegradable materials. If you would like to know more about our products, please contact us.

Copyright © HUBEI HYF PACKAGING CO., LTD. All Rights Reserved | Sitemap

| Powered by

SEOKeywords:Shrink Wrap Film Customized Biodegradable Shrink Film Pvc Shrink Film Rolls Flexible Packaging Film Petg Shrink Film Properties Custom Printed Shrink Film High Shrink Petg Shrink Film China Pvc Shrink Wrap Film Shrink Sleeve Plastic Label Films Shrink Sleeve Packaging Pvc Shrink Film Manufacturing Process Pvc Super Clear Shrink Film Heat Shrink Film Roll Pvc Shrink Film For Bottle Label Price Shrink Wrap Uses China Shrink Film Pvc Clear Shrink Film Printable Shrink Film Plastic Shrink Film