According to the analysis of IHS Markit, a leading global consulting firm, the "restrict or stop using plastic bags and other single-use plastic products" initiative launched by Western European countries will further boost the market demand for biodegradable plastics. It is expected to reach USD 1.8 billion in 2024, of which PLA will play an important role, with the fastest development in food packaging and other fields.

The application of PLA in the market is mainly in the three major fields of packaging, medical and textile, among which the application in the packaging industry is particularly prominent. HYF is a company producing high quality pla flexible film and shrink sleeve packaging, pharmaceutical industry and biodegradable materials, the following is a demonstration of the manufacturing process in our factory.

PLA film mainly has high transparent film, heat shrinkable film, pellet co-mingled blown film bags and PLA-based composite film. PLA film can replace traditional film materials as new packaging materials, such as Wal-Mart supermarkets require the use of fully degradable PLA film bags to replace the traditional non-degradable PE bags, and Japanese electronic products have also begun to use PLA nano-composite film packaging.

Due to the degradability of PLA, it is used to produce water and juice bottles, but this market is limited. Injection-stretch-blow molding is the typical production method of PLA bottles, which are mostly used in short-term shelf food packaging. The European market has launched yogurt cups and beverage packaging bottles made of PLA that can meet the relevant EU standards for food containers. In the domestic market, PLA is coated on paper to make laminated paper cups, which are used for various waterproof and oil-proof food packaging.

PLA foam is biodegradable and can be used to produce disposable food and beverage utensils (such as fast food boxes, instant noodle bowls, etc.) and cushion packaging liners without producing white pollution, especially PLA heat-resistant tableware will become more practical. Foaming is an effective way to use PLA at low cost.

Compared with traditional PE and PP materials, PLA has a higher melting point and better processability.

The hardness and mechanical properties of PLA are similar to those of traditional resins, and it has better transparency and excellent gloss, etc., making it more suitable for use as a packaging material.

The oxygen and water vapor barrier of PLA is not enough to protect food containing fats and oils.

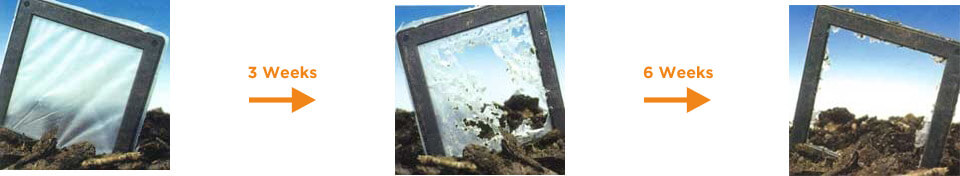

In addition, the degradation cycle of PLA is not well controlled, and its performance will be degraded when it is prone to different degrees of degradation or hydrolysis in use.

The material cost is more than 2.5 times of traditional PE and PP, and these should not be ignored.

For more information of packaging materials, please contact us, we have pla shrink film, petg shrink film, rpetg shrink film and so on.

Copyright © HUBEI HYF PACKAGING CO., LTD. All Rights Reserved | Sitemap

| Powered by

SEOKeywords:Shrink Wrap Film Customized Biodegradable Shrink Film Pvc Shrink Film Rolls Flexible Packaging Film Petg Shrink Film Properties Custom Printed Shrink Film High Shrink Petg Shrink Film China Pvc Shrink Wrap Film Shrink Sleeve Plastic Label Films Shrink Sleeve Packaging Pvc Shrink Film Manufacturing Process Pvc Super Clear Shrink Film Heat Shrink Film Roll Pvc Shrink Film For Bottle Label Price Shrink Wrap Uses China Shrink Film Pvc Clear Shrink Film Printable Shrink Film Plastic Shrink Film